Gap Fillers Lecture Series -

SITU Fabrication transcript

Presented by Michael Brotherton, AIA

SITU Fabrication – Michael Brotherton, AIA

Lecture held on September 23, 2025, 12 PM - 1 PM in Long Lounge, Building 7

Michael Brotherton:

It’s a pleasure to be here, and thanks for inviting me. I think it’s great you’re focusing this year on mechanics and how things are built. That’s definitely an important part of the profession that often gets overlooked in favor of flashy renderings.

I’ve put together a presentation to walk through some of our projects. Since we’re a small group, feel free to interrupt, raise your hand, and ask questions at any time.

About SITU

For those unfamiliar, SITU is a three-division company, and we think of ourselves as an unconventional design practice:

Studio – Our architecture division, focused on workplace and institutional projects in New York.

Research – A more experimental division, working in social justice and advocacy using architectural visualization tools. They produce a lot of powerful digital content.

Fabrication – The division I’ll be speaking about today.

Each division has its own focus, but we often collaborate. For example, last year our fabrication team built models for museum exhibitions produced by the research group. The common thread across the practice is exploration, finding novel ways to design and build.

Fabrication Division

We’re not tied to one material, fabrication method, or technology. Instead, we’re drawn to projects with complex geometries, unusual problem-solving requirements, or a need for custom detailing. Our work spans residential, institutional, fine art fabrication, and product design.

On our website, you’ll see a lot of highly unique projects, but as a business, we also do plenty of straightforward cabinetry and millwork, the “bread-and-butter” projects that help sustain us financially while giving us room to pursue the more experimental work.

Design Assist and Collaboration

Many of our projects begin in a design-assist capacity. For specialty elements, the traditional design–bid–build process often doesn’t work well, costs aren’t clear until late in the process, which can lead to value engineering or even scope cuts.

As a specialty contractor, we prefer to get involved early, work with the design team to solve problems, and make sure the scope is properly understood and priced before it risks being eliminated. Our goal is always to preserve design intent while staying within budget and schedule.

Project Examples

Lobby Feature Wall with COOKFOX Architects

The architects envisioned a curvilinear reception wall with double curvature. Initially, they considered veneer, but the geometry wasn’t feasible with that material. Together, we developed a solution using stacked laminated solid wood.

Parts were cut on the CNC, nested and labeled, then stacked onto an armature to form the surface. While the process can be wasteful, it produces spectacular results for certain geometries.

Solid wood moves seasonally, so we designed for expansion and contraction with interlocking joints and backer details.

We also fabricated the black acoustic panels in this lobby, requiring coordination between multiple material systems.

Sanford Biggers, Madrigal. Edward and Joyce Linde Music Building, MIT

Madrigal is an 18-foot-tall outdoor sculpture by artist Sanford Biggers, commissioned for MIT’s new Edward and Joyce Linde Music Building. The work transforms six distinct quilt patterns into a monumental three-dimensional form, producing a dazzling interplay of geometry, pattern, and color.

Our role at SITU Fabrication was to help translate Biggers’ intricate vision into a durable, buildable structure that could thrive outdoors.

Design Development

The process began with the artist’s sketches and quilt studies, which we converted into detailed parametric models. This allowed us to explore how the two-dimensional quilt patterns could unfold into a complex 3D geometry.

We worked closely with structural engineers to iterate designs that balanced Biggers’ aesthetic goals with the structural requirements of such a large-scale outdoor installation.

Fabrication

The structure combines aluminum and steel tubes and brackets (a kind of erector-set-like framework) with powder-coated aluminum plates. These plates support CNC-cut acrylic solid surface tiles in 13 colors, sourced from five different international suppliers.

To ensure long-term vibrancy, we conducted weather testing to select UV-resistant colors.

Because the sculpture consists of thousands of individual pieces, we developed an extensive labeling and tracking system to ensure accuracy. One-to-one mockups were built to confirm details, and large assemblies were pre-fabricated in our shop to streamline installation.

Installation & Outcome

Thanks to pre-assembly, on-site installation at MIT was reduced to just a few days. The completed piece demonstrates new ways of integrating solid surface with metal structure, showing how materials can be pushed into new aesthetic and technical roles.

As a centerpiece for the MIT campus, Madrigal embodies the dialogue between art and engineering, transforming quilt traditions into a monumental, contemporary landmark.

Elevator Lobby Panels for Architecture + Information (A+I)

Originally conceived as perforated aluminum panels. Through prototyping, we developed a system of CNC-milled aluminum with integrated backlighting.

We worked with the design team to refine hole sizes and spacing, and also tested milling speeds and sandblasting to eliminate tool marks.

The final system was straightforward to install and produced a striking result. In fact, the refinements made it more impactful than the initial design.

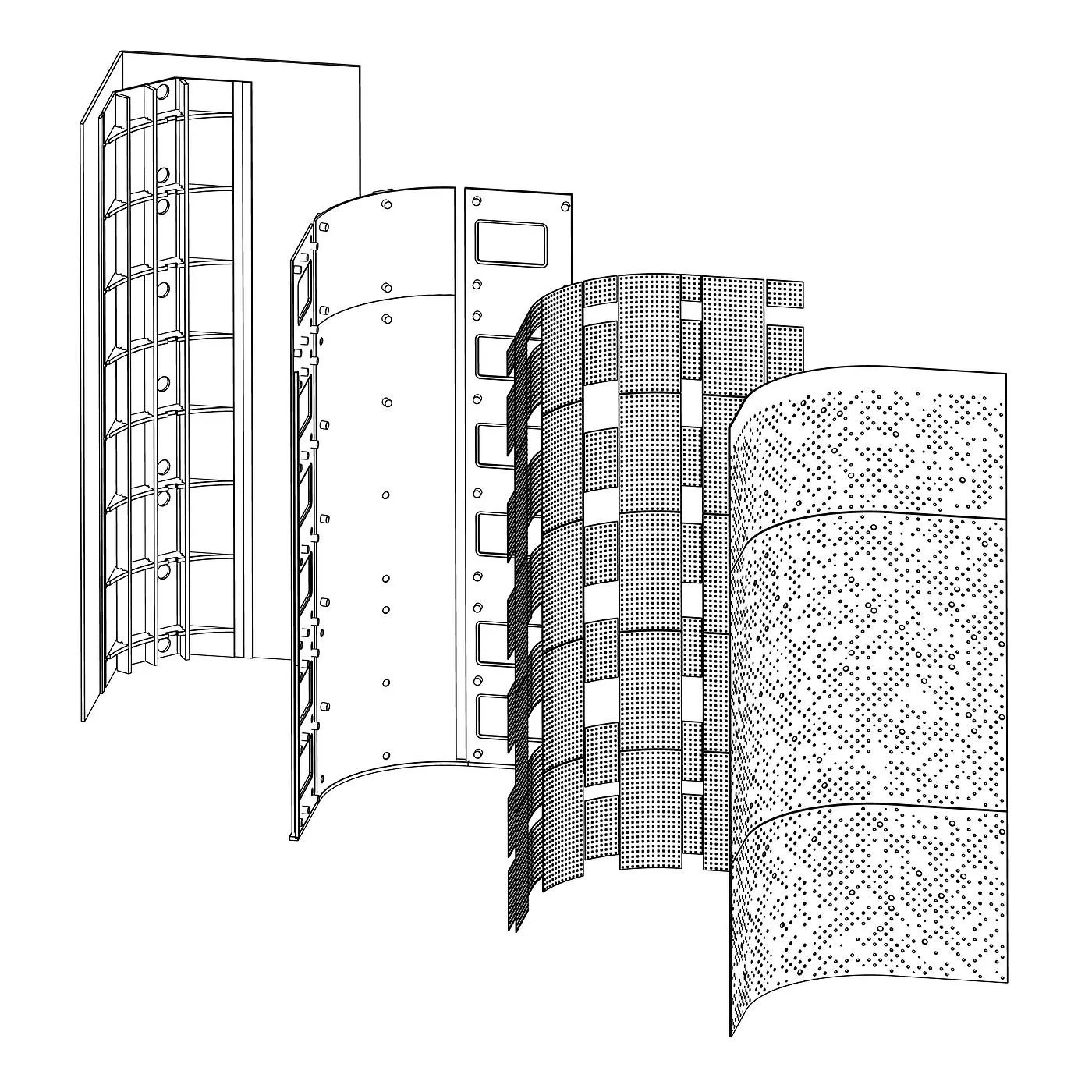

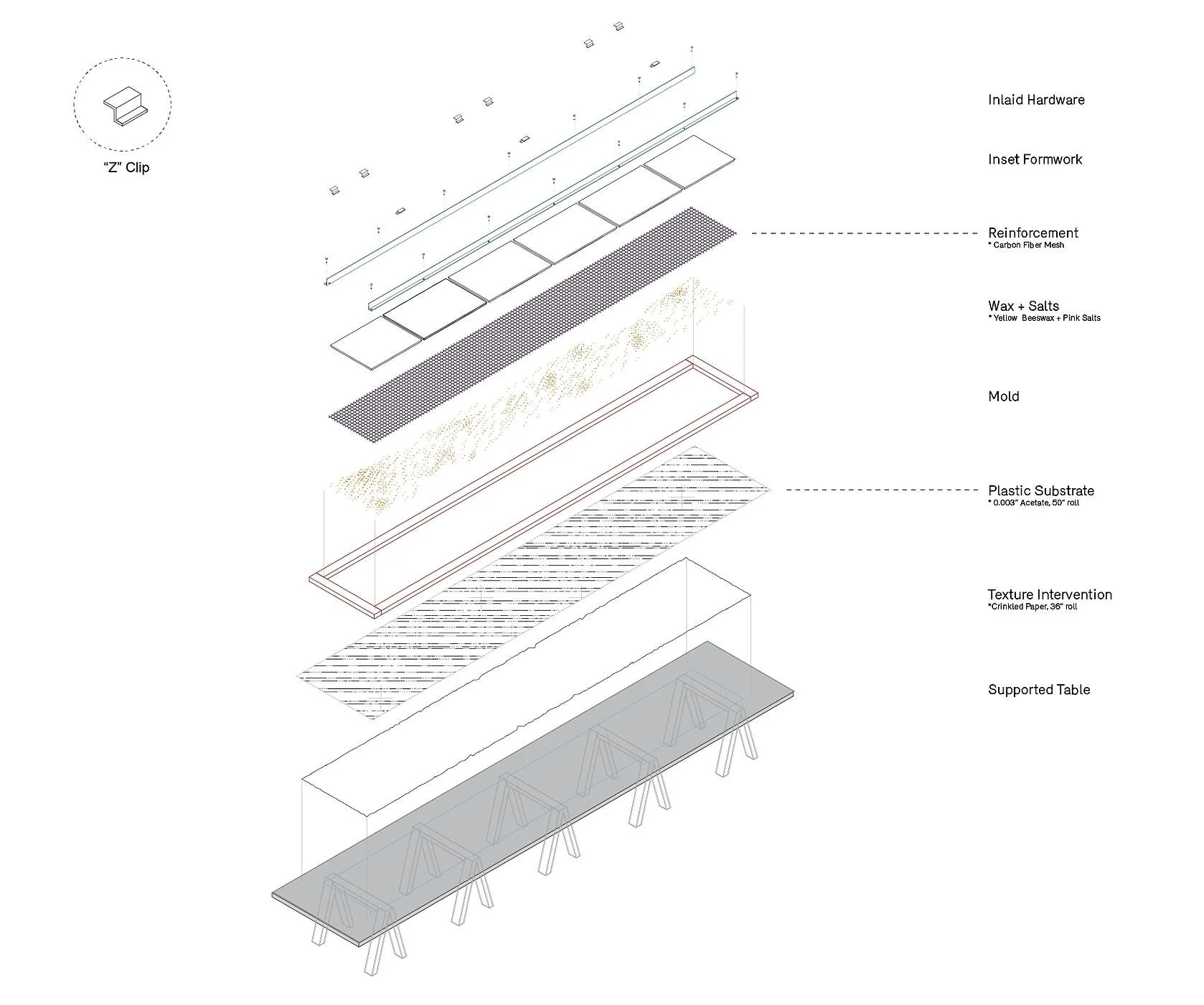

Concrete Facade Panels for One John Street (with Alloy)

For developer Alloy, we designed and built a series of sculptural concrete panels for the entry of One John Street, a residential building in Brooklyn Bridge Park.

Through iterative sampling, we experimented with erosion-inspired and encaustic aesthetics, eventually developing a casting method that allowed both consistency and variation.

Fiber-reinforced concrete was cast against layers of crinkled paper and acetate, with beeswax and salt applied directly to the surface. After curing, the 17-foot-tall panels were moved to a custom oven table, where the wax was melted out and most of the salt removed. Some crystallized salt remained embedded in the surface as bright accents against the dark concrete.

We produced a total of 64 panels, cladding both the interior and exterior portions of the building. Exterior panels were left untreated, allowing their surfaces to evolve naturally over time.

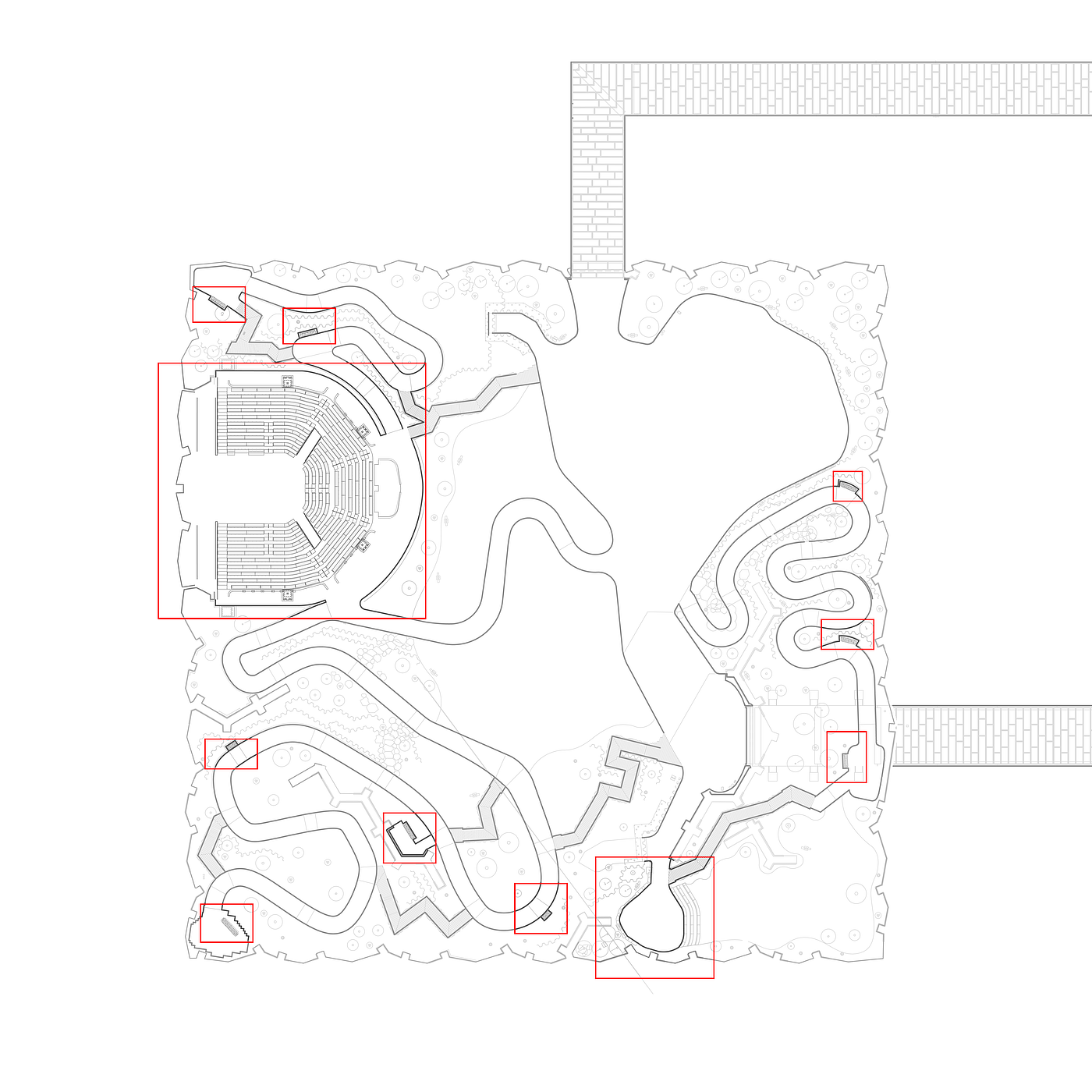

Little Island Landscape Seating

Little Island is a public park in the Hudson River, designed by Heatherwick Studio, MNLA, and Standard/Architects. Our scope was seating features across three main areas: the Amphitheater (“the Amph”), the Glade, and trail benches.

We combined design-engineering, digital fabrication, and artisanal woodworking to create durable, sustainable, and comfortable seating that matched the park’s whimsical character.

The Amph

A 700-seat amphitheater for live performances. Comfort was key, so we steam-bent and CNC-milled black locust slats into sculptural seats. Black locust was chosen as a sustainable, durable, and locally sourced hardwood.

The Glade

A smaller, more casual performance space at the park’s south end. Communal tiered seating was constructed from large black locust timbers with sculpted edges, shaped using manual tools such as chainsaws and grinders for a more artisanal, relaxed feel.

Trail Benches

Ten long benches are placed throughout the park’s rolling trails. Each was built from heavy black locust timbers mounted on patinated bronze legs.

Some benches include backrests, others do not; all were hand-shaped into continuous, soft curves, mimicking natural live edges while maintaining engineered stability.

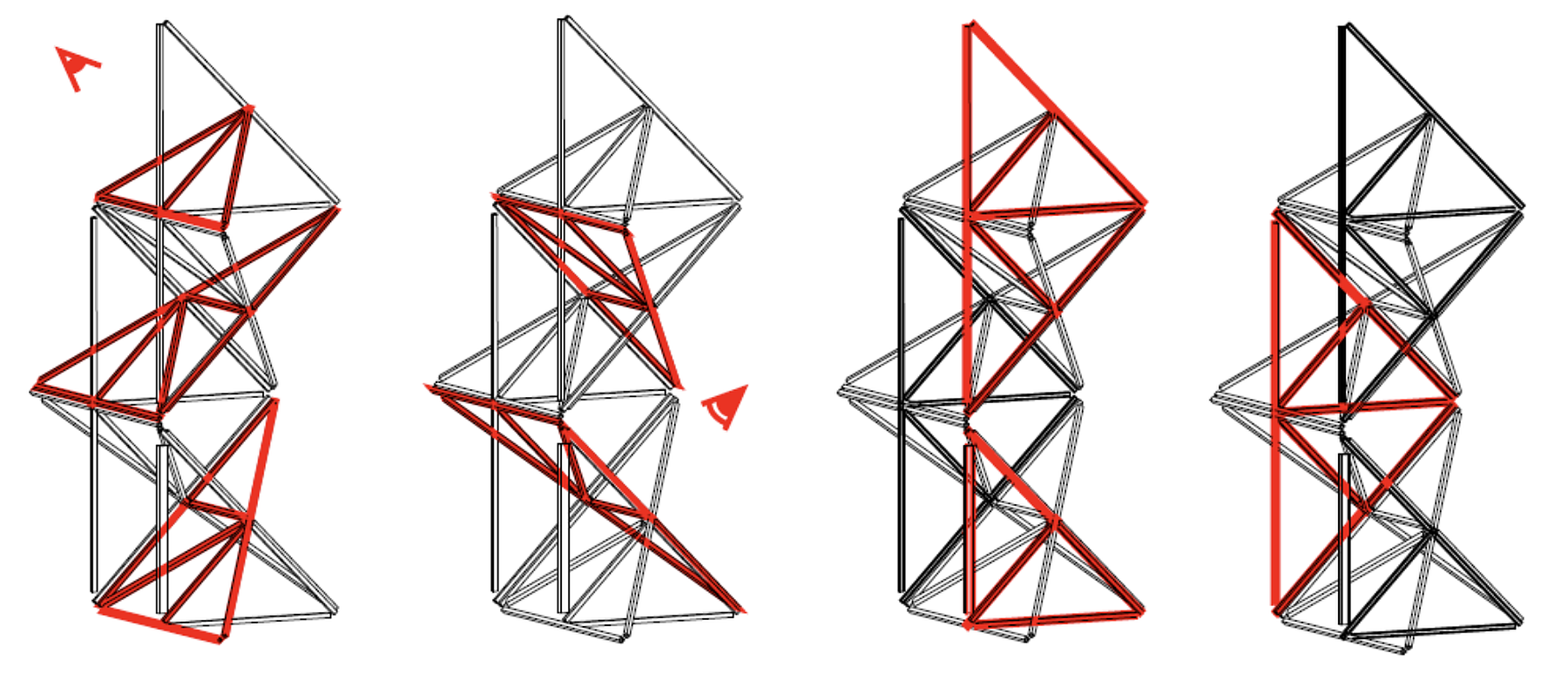

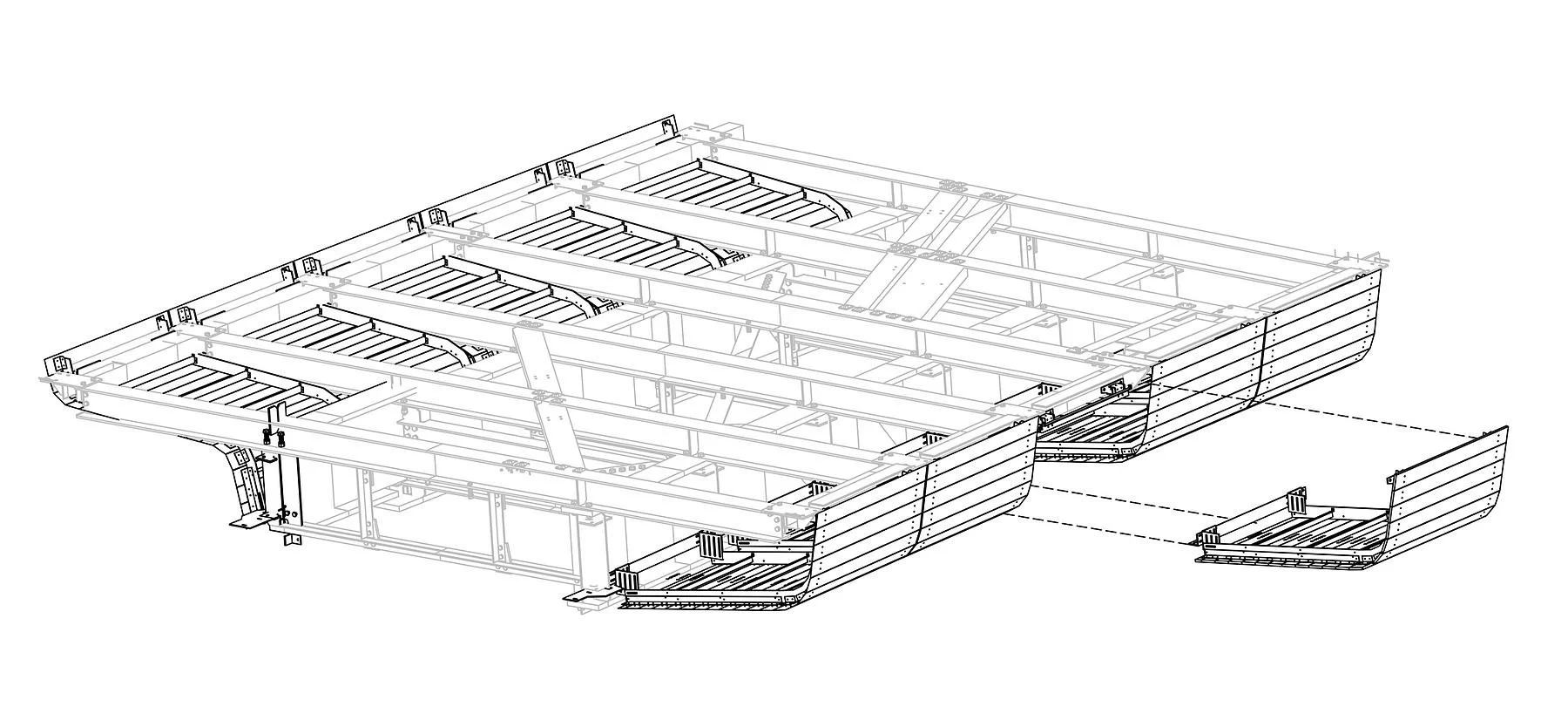

Providence River Pedestrian Bridge (with inFORM Studio)

The Providence River Pedestrian Bridge reconnects neighborhoods once divided by the I-195 highway. Designed by inFORM Studio, it has become a civic landmark with plazas, overlooks, and gathering spaces.

Our role focused on the wood cladding system, comprising 250 unique panels that wrap both sides of the bridge. Each module combined a lightweight stainless steel armature with wana wood, a durable but less dense hardwood chosen over ipe.

Using parametric tools, we engineered thousands of custom connections and modularized the system to preserve its organic form while accelerating production and reducing waste.

Panels were fabricated, delivered, and installed by barge, with demountable connection details to allow long-term maintenance.

Lessons

Details evolve - expect refinements as materials and methods develop.

Plan for installation - eventually, others will assemble the work; clarity and simplicity are crucial.

Material expertise - know when to bring in outside collaborators.

Designing the process is just as important as designing the object.

Q&A Highlights

Q: Have you ever had a project where you just said, “No way, this can’t be done”?

A: Yes. Sometimes we hear that other fabricators who are even more specialized in their field have declined a project due to technical reasons. In those cases, it’s about reframing the design intent into something achievable, without stringing anyone along or overpromising.

Q: Why clad the entire Providence Bridge in wood, even the sides?

A: That was the architects’ decision, driven by placemaking and creating a warm, communal character. From kayaks or the shoreline, the effect is striking. But yes, it was extra work and cost, requiring careful modular detailing for maintenance.

Images courtesy of SITU Fabrication